Water heating is essential for our daily life and household activities. We use it to shower, cook, wash dishes, launder our clothing, and for our personal hygiene. Unbeknownst to most, water heating alone is the second largest home utility expense! The average family uses 64 gallons of water each day, accounting for up to 20% of your home’s energy usage after heating and cooling. Studies show about 27 million U.S. homes have out-of-date water heaters. If your water heater is passing the 10 year mark, it may be time to start thinking about a replacement before it fails and floods your basement 🙁

Heat pump water heater’s (HPWH’s) use half the energy a standard electric hot water heater (ERWH) would consume. The data provided from multiple studies proves HPWHs are one of the most effective methods available for considerably reducing energy use and costs for domestic hot water heating. They are 2-3 times more efficient than a tankless/on-demand hot water heater and also benefit from decreased operating costs. HPWH’s can save a family of four more than $3,500 over their lifetime (heat pump water heaters last 10-15 years), equating to a savings of approximately $300 each year! Although the initial cost of a HPWH is greater than a standard electric hot water heater, they pay for themselves within 2-5 years and long after the return on your investment, your water heater will continue to save you money and energy for the entirety of it’s equipment lifespan. The larger your family and the more hot water you use, the quicker your payback will be.

It’s important to understand that energy efficient products are typically more costly compared to their less-efficient and economically disadvantageous counterparts but they have relatively short payback periods, increased energy savings, superior performance, and are better for the environment 🙂 Because HPWH’s have no combustion process and don’t burn fuel, they leave no carbon footprint or greenhouse gas emissions. For comparison, a family of four can prevent 20 tons of greenhouse gas emissions by updating their standard electric water heater (ERWH) to a new heat pump counterpart. And if every standard domestic electric water heater less than 55 gallons were replaced with an energy-efficient HPWH, the country as a whole could save $8.2 billion in energy (kWh) each year, equivalent to 98 billion pounds of greenhouse gases, or 9 million cars.

Basic considerations for a HPWH include adequate clearance and space for the unit. Heat pump water heaters require a minimum of 750 ft^3 (the size of 10×10 room with 7 1/2 ft ceilings) to 1,000 ft^3, for proper air supply and circulation. They are generally taller, heavier, and wider than an average ERWH and may require additional piping configurations near the install location, to prevent the possibility of heat pump damage due to leaking pipes. The ambient temperature of the space where the HPWH is located is another important stipulation for proper installation and efficient performance of the unit. The area in which your HPWH is located must maintain temperatures between 40-90 degrees year-round. Heat pump water heaters cannot operate in freezing temperatures!

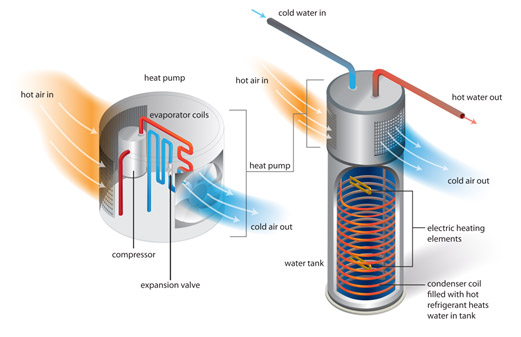

For those of us who live in cold climates, an ideal location for a HPWH would be in a semi-conditioned basement near a furnace or boiler where it can absorb waste heat from your heating appliance without drastically affecting the space conditioning in the rest of your building envelope. Because HPWH’s actually cool the space where they’re located, anywhere between 2-6 degrees, depending on the demand on the water heater, it is not recommended any HPWH be installed in a conditioned space that utilizes heating sources most of the year. The HPWH creates this slight cooling effect due to the fact that it operates by extracting thermal heat energy from the ambient air and transferring it to your storage tank for the purpose of heating your water.

A HPWH operates on the same principles as a heat pump refrigeration cycle used to heat or cool your house, by condensing and evaporating refrigerant in a closed-loop cycle to create a heating or cooling effect. They produce hot water by extracting heat energy (typically measured in mmBTU’s) from the surrounding air and transferring it into the water stored in your tank. In cold climates, which accounts for most of the United States, HPWH’s experience a net heating penalty on their space conditioning energy usage. Whereas, people living in year-round hot climates, experience a net cooling benefit to their space conditioning. Your HPWH contributes to this net cooling benefit by effectively dehumidifying the space and producing cool exhaust air as a result. This is because water vapor from the ambient air is circulated through the evaporator coils inside the unit, which condense the water, effectively removing the excess moisture/humidity within the space while expelling cooler, dry air. (Sorry VT folks this net cooling benefit won’t apply to us, except during the hot summer months!) This is why HPWH’s should not be installed in a “conditioned” space in cold climates because they will force your heating system to work harder to displace the cool and dehumidified discharge air coming from your heat pump unit, reducing savings and efficiency as well as increasing your potential payback time. For those interested in purchasing the best HPWH for our colder climate, consider an HPWH that specifically meets the ‘Northern Climate Efficiency Specification’ created by the NEAA (Northwest Energy Efficiency Alliance). These HPWH’s typically contain compressors that are able to operate at lower temperatures to provide improved capacity and efficiency in cold climates.

The capability and performance of domestic hot water heaters in the U.S. are measured based on the energy factor (E.F.) of each unit. The energy factor is determined by the ratio of energy delivered to your water, divided by the amount of energy actually used. Standard electric resistance water heaters (ERWHs) have an E.F. of 0.9, versus a HPWH’s energy factor of 2.0-2.5. The annual electrical usage (in kWh) of a HPWH with an E.F. of just 2.35 amounts to approximately 1,856 kWh/year, versus an ERWH’s yearly electrical usage of 4,879 kWh/year. The rough estimate for a HPWH install is around $2,800 versus the install cost for an ERWH which is around $1000. However, the annual operating cost for your HPWH will amount to around $198, versus the annual operating cost of a standard ERWH which amounts to around $520, over $300 more than a HPWH each year! For some, purchasing a HPWH could provide enough electrical savings to classify you in a lower usage tier, providing your household with an even more affordable utility rate. Households that choose to switch to an HPWH will be able to pay for the unit (including it’s installation cost), within 2 to 5 years. As stated previously, after the return on your investment, the HPWH will continue to save you thousands in utility costs throughout it’s lifetime.

In addition to providing a reliable source of domestic hot water, substantial energy savings, and a healthier home environment, HPWH’s are eligible for both federal and tax rebates to encourage more consumers to make the energy efficient switch! Efficiency of Vermont currently offers a $400 mail in rebate for HPWH’s less than 55 gallons (valid 12/01/15 to 6/30/16). A federal tax credit up to $300 is also available for newly installed HPWH’s with an E.F. of at least 2.0 from 1/01/15 to 12/31/15. That’s a potential savings of $700 on your new HPWH unit!!! Check out dsireusa.org and type in your residence’s zip code to view the state incentives for renewables and energy efficiency available near you. (Heat pump water heater rebate information is located under the category of ‘Residential Energy Efficiency Tax Credit’, once you enter your zipcode). Also look at energystar.gov/about/federal_tax_credits for more information on the available federal tax credit for your HPWH.

HPWH’s are intricate mechanical vapor compression units that require proper installation and future service by a professional. Inadequately installed units significantly impact the performance and efficiency of your unit. Also, keep in mind it’s important NOT to downsize the storage tank for you HPWH, doing so will also effect the efficiency of your unit. If your tank is not adequately sized the HPWH will not be able to recover and heat water fast enough once the full content of the tank is circulated through the household due to high hot water demand. Make sure to choose a HPWH with the highest E.F. (energy factor) and the highest F.H.R (first hour rating), which details the amount of hot water (measured in gallons per hour – GPH) the heater can supply once the tank is filled.

Aside from the precedent space and ambient temperature requirements, HPWH’s are relatively easy to install and maintain, requiring only regular cleaning of air filters and inspection of condensate lines. Given the low cost of drain pans, ensure your installer utilizes blocks and a drain pan underneath your unit to prevent condensate line or pump failure and possible flooding due to an obstruction. Every water heater, regardless of whether it is a hybrid heat pump version or not, should also have the water drained from the tank monthly to prevent hard water deposits from compiling. For optimum performance, make sure to have your water lines and storage tank insulated, which will effectively raise your water temperature an extra 2-4 degrees as well as prevent standby losses as the water travels through your home 🙂

Thank you for reading and don’t forget to contact GSK Climate Control for your future HVAC needs. Serving Southern VT & the surrounding regions since 1985.

Call: 1-802-362-5444