A filter’s primary purpose is to protect your HVAC (heating, ventilation, & air-conditioning) system’s heat exchange coils from collecting dirt and debris, which significantly decreases thermal transfer, as well as system capacity and function. The secondary purpose, is to maintain and clean the air circulating throughout your system and into your home or building. Proper filter maintenance is absolutely imperative to keeping an efficiently functioning system while ensuring your indoor air stays fresh and clean.

In a previous blog, we discussed the importance of PREVENTATIVE MAINTENANCE which provides a clean, properly-functioning, and efficient system through annual or bi-annual system “tune-ups”. Ensuring you change or clean your filters (depending on whether, they’re washable or replaceable) every 90 days in-between these annual/bi-annual PM visits can be the difference between your most ideal comfort levels and other-wise preventable repairs and inopportune service calls. Whether you own a furnace, heat-pump, air-handler, mini-split, or multi-split unit(s), keeping up with your filter change-outs and cleanings, is one of the single most effective and important maintenance tasks – not to mention, the easiest!

When your HVAC system’s air filter gets dirty and clogged with microorganisms such as; outdoor pollutants, dust, dander, insects, exhaust fumes from fossil fuel appliances, plant and mold spores, bacteria, VOC’s (Volatile Organic Compounds in the air produced by cleaning chemicals, varnishes, paints, aerosols, etc.), and various other contaminants, this creates a barrier which impedes the airflow, heating/cooling capacity, energy-efficiency, and proper-operation of your equipment. Dirty, clogged air filters create a high resistance to air flow through your heat transfer coils, to your ventilation, and eventually into your home, causing high static pressures in your ductwork or refrigeration system which results in malfunctioning fans, compressors, and blower motors. Without proper airflow your system’s heat exchange coils cannot heat or cool to the specified capacity, resulting in less effective heating/cooling and severely impacted space conditioning within your home or building. High pressures and resistance in your HVAC system place additional stress on your equipment, creating increased operating costs, freezing heat exchange coils, and tripped limit switches due to overheating, eventually leading to premature equipment failure. 🙁

Ill-maintained air filters, if left un-changed, can become a primary source of pollution in your home, exacerbating allergy symptoms, respiratory distress, and general health issues. It’s important to remember that all of the air that passes through your HVAC equipment and through to your ventilation to condition your home, passes through your AIR FILTER(S)! Keep in mind that using the wrong-size, type, or rating of filter for your HVAC system can be just as bad for your system as having a dirty filter.

There are several types of HVAC/R system filters on the market:

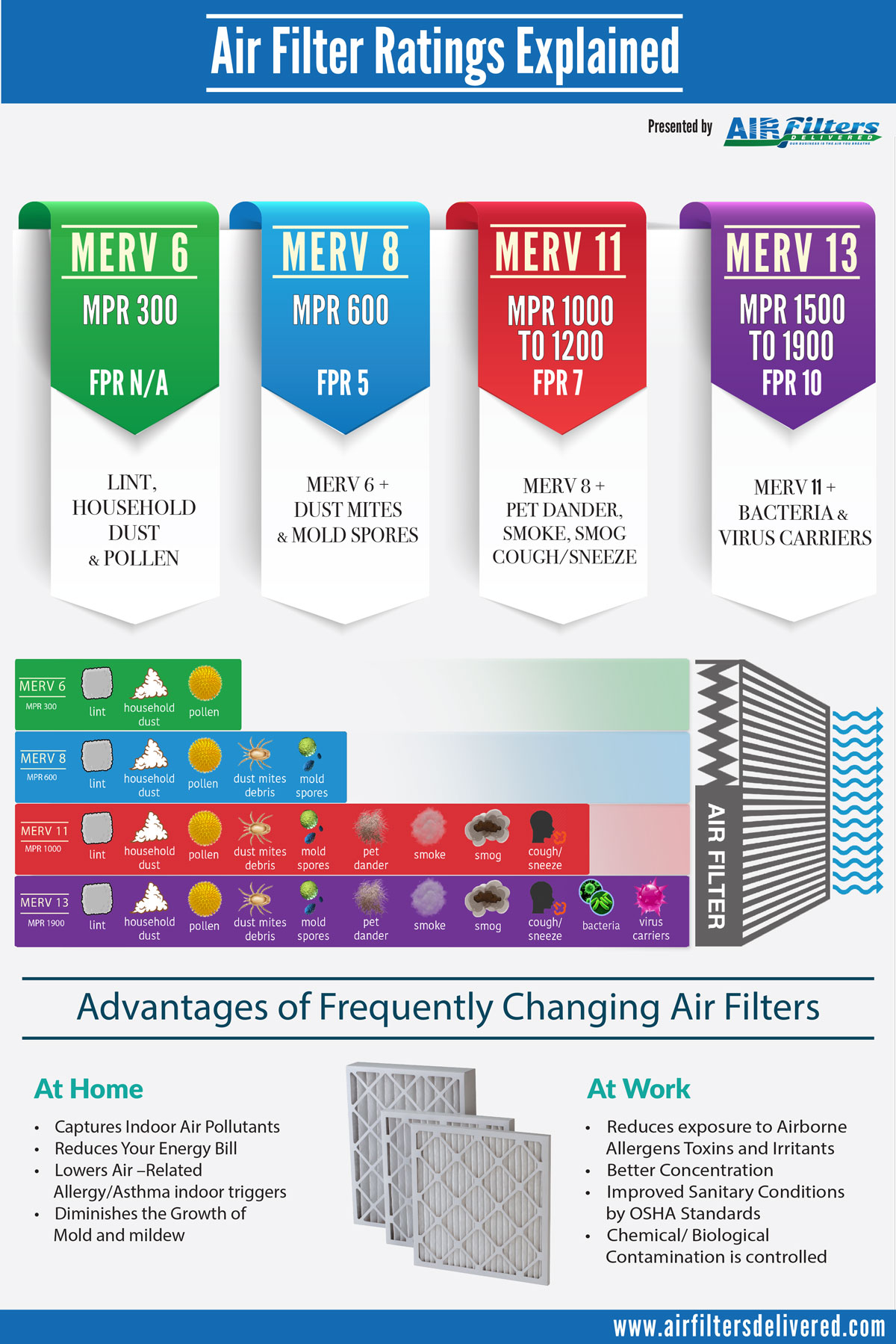

- Fiberglass – throwaway/common type. Effective at protecting coils but doesn’t improve IAQ (indoor air quality) considerably. Fiberglass fibers are interwoven and layered together, then reinforced by a metal grating to support the filter from collapse. MERV 1-4.

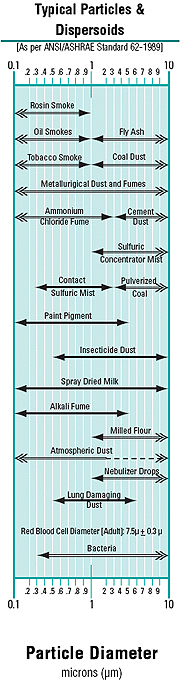

- Polyester/Pleated – similar to fiberglass but more efficient. Typically have a slightly higher resistance to airflow and higher dust particulate filtering efficiency. Filter approximately 45% of particles 0.3 microns to 10 microns. MERV 6-8.

- HEPA – (High Efficiency Particle Arrestance) Originally developed during WWII to block radioactive particles from escaping nuclear laboratories. Meet DOE Standard STD-3020-97. Typically found in hospital, industrial, and sterile environments. Filters 99.97% of all particles 0.3 microns or smaller. Ideal for people with sever allergies. Most expensive air filter. MERV 13-16.

- Washable – Washable filters are very common in Mini/Multi-split heat pump or central air systems. They’re extremely cost effective, however the MERV ratings are typically in the low to mid-MERV rating range. These filters can simply be washed with warm pressurized water and/or simple cleaning solutions to remove buildup and then placed back in the unit.

- Electrostatic – Some Mini/Multi-split HVAC units utilize electrostatic filters that generate electricity as air passes through them, so that dirt and debris is electro-statically adhered to the filter. Some disadvantages of electrostatic filters include the conductive carbon emissions they produce and the fact that some react with certain cleaning chemicals to form toxic formaldehyde.

*If you’re concerned about moisture and high-humidity in your system/home, make sure to ask for a filter with hydrophobic, thermally-bonded fibers. Newer mid-range pleated filters have adopted synthetic materials that are chemically-bonded to prevent shedding and resist humidity.*

MERV ratings were developed by ASHRAE in 1987 to rate the efficacy of different types of air filters. Higher MERV ratings equate to higher amounts of particle filtration and increased IAQ (indoor air quality). However it’s important to understand the severe implications of using a very high-efficiency filter in a system that is manufactured for a mid-range polyester/pleated-type filter. HEPA filters are impractical for most residential systems, due to the fact that the filter media is so dense it creates a large pressure drop in the system, similar to the effect a dirty, but properly-sized and rated filter would do. In fact, most mid-range (MERV 7+) filters perform similar enough to a HEPA filter in catching small particles that can contaminate your HVAC system and the air. Mid-range filters are also much more cost-effective.

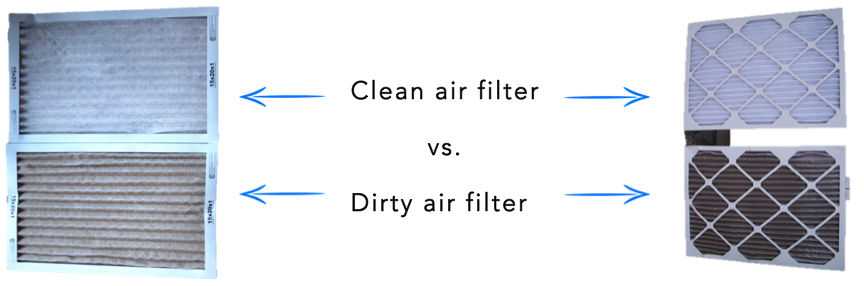

A good ‘rule of thumb’ when looking to change your HVAC system’s air filter, is to take it out of it’s dedicated slot and visually inspect it. If it’s damp, change the air filter immediately. Damp air filters are a prime vehicle for mold growth and can spread mold spores into your ductwork and throughout your home, creating or intensifying a breeding ground for health issues. When dirt and other particulates are able to pass through your filter and accumulate onto your system or ductwork, this can hinder system efficiency up to 40%, impeding the efficiency and function of heat exchange and distribution sources! Also if you can’t see through the filter media when held up to light, it’s probably time you changed it! Keep in mind, maintaining your air filter as recommended can actually decrease your energy costs anywhere from 5 to 15%, by keeping your system operating at it’s ideal designed load and capacity.

Equipment malfunctions and failures are a common symptom of dirty air filters in your system, which are completely avoidable. Remember to change your air filters at the least every 3 months and safeguard your equipment and home from poor air quality, lack of cooling/heating, inefficient equipment operation, increased energy bills, costly repairs, and inopportune service calls! Most system air filters are located in-between the main equipment source (i.e. furnace, air-handler, etc.) and the return duct or blower compartment. Filters must be properly-sized, rated, and installed, facing a certain direction. Arrows along the outer edge of your filter indicating a specific direction should be pointing towards the main body of your unit. Check for the original equipment manufacturer’s recommendations before purchasing an air filter, or ask your HVAC contractor if you’re not sure, to ensure prime system function with the correctly sized and rated filter.

Thank you for reading! 😉

Taylor Kristiansen,

commercial & residential plumbing, heating, ventilation, air-conditioning, & refrigeration, & custom sheet metal fabrication

serving Southern VT & surrounding regions since 1985

call: 802-362-5444

Resources: